FACE GRAIN

Perfect for serving cooked or cured items, fruits, veggies, dip bowls, chips, etc. As you can see in the image to the left, the face of the grain makes a stunning backdrop for a serving board or charcuterie board. Face grain should never be used as a cutting surface.

EDGE GRAIN

(Otherwise known as side grain). In a nut shell, edge grain is the face of the grain (aka face grain), cut into strips, and rotated 1/4 turn, then glued together. This process provides a more fibrous surface for cutting and chopping. It is a great option in cutting board surfaces while still providing an esthetically pleasing look. In addition, this style of construction is a very stable structure because the fibers of the wood meld quite well to each other and is less prone to warping. It is less labor intensive to build than end grain cutting boards, making it a more affordable option in cutting boards. It can also be used as a charcuterie board because it is usually less weight, easy to maneuver, and provides a surface that will stand up to cheese knives, etc. Edge grain is a great choice in cutting boards but we quite often use it in our charcuterie construction too. It provides the best of both worlds when using serving trays. You can find the construction process of our boards in the listing details. Visit our charcuterie boards.

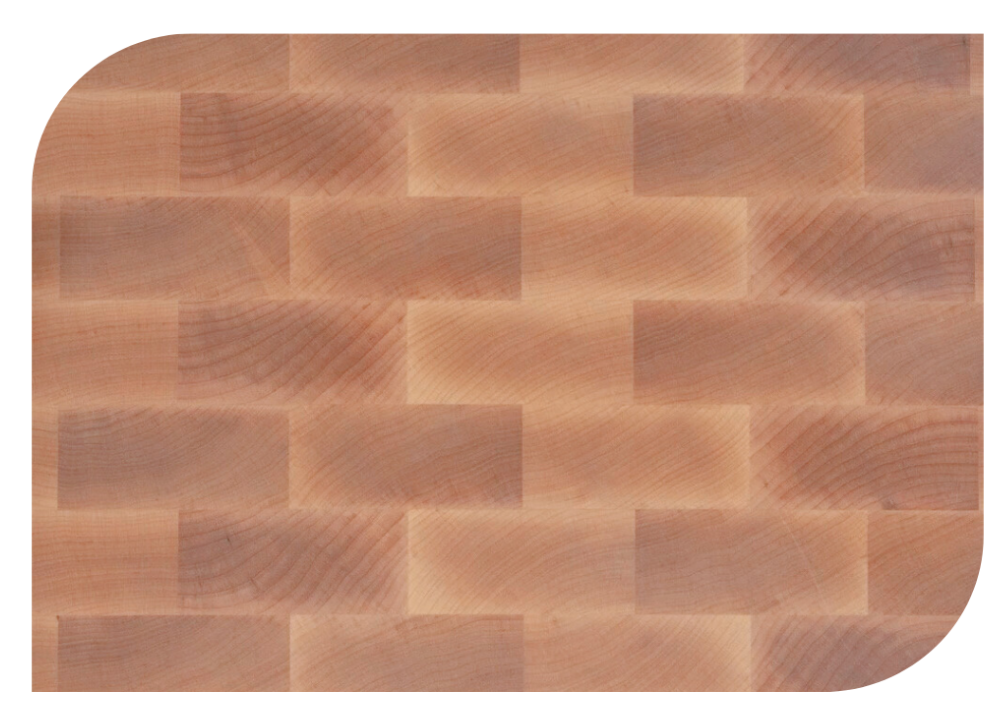

END GRAIN

End grain is as described, "the end of the grain". The end fibers of many strips of hardwood are pointed upward and glued together. The maple butcher block checkerboard pattern is probably the most recognized in this style, but there are many more configurations. Although this is the most labor intensive to construct, it is also the most durable. End grain is easiest on a knife blade and the most self healing as well. All those fibers want to pop back into their previous position. End grain boards or blocks tend to be heavier because of their over all design and density, providing a solid working surface. They are well suited for any kitchen but especially someone who enjoys cooking.